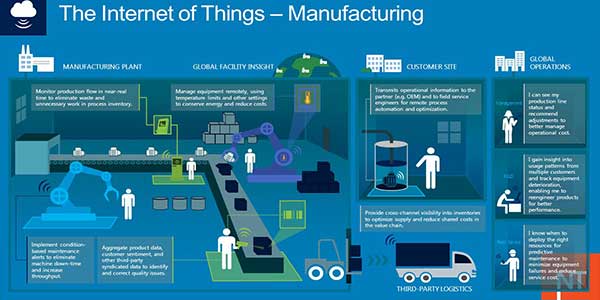

For a decade, the Internet of Things (IoT) has been growing across the globe. The user domain is the most obvious IoT importance. However, the biggest champion of this smart technology is perhaps the Industrial IoT (IIoT).

As per the prediction, the industrial IoT (IIoT) market for devices & technologies is projected to rise from USD 77.3 billion to USD 110.6 billion by 2025, at a CAGR of 7.4 percent. Let’s check some key points to know how Industrial IoT is helping in the manufacturing industry.

Table of Contents

Advantages Of The Industrial Internet Of Things (IIoT)

1.) Asset Management::

Create a facility that provides a certain product; the operative needs to check periodically at what level the product has reached, improve the power of the motor based on output timings, and control production by looking at entry and exodus points. In this case, reducing human intervention and intelligently monitoring the properties will be helpful. With the aid of IIoT, smart factory systems can monitor asset positions with smart sensors, track demand-supply demands, and manage the workflow, records, and output accordingly.

2.) Predictive Analytics:

By implementing IIoT, manufacturers can better track the condition of the equipment, predict the time frame to meet such targets, and monitor machine-by-machine maintenance requirements. Predictive analytical instruments assist engineers in determining the root cause of a problem and working on the contingency plan, warning future failings a lot more early. As we move with this ecosystem, there will be more data in the production line to provide more visibility to manage complex scenarios that lead to a robust framework.

3.) Effective And Productive Process:

In the automotive sector, mechanical machinery needs daily servicing and maintenance. If the equipment experiences unanticipated damage, both time and resources can be wasted on registered production. Production assisted by IoT will prevent production downtime by the maintenance of equipment before failure. Finally, through enhanced analytics production lines would see increased efficiency and strengthened decision-making.

4.) Safety Operations:

Manufacturers have started investing in smart IT-driven production solutions, thus saving time & money. Industry 4.0 is implemented such that industrial users benefit from asset management, predictive analytics, reliable and effective processes, and security operations.

While IIoT has undoubtedly demonstrated its principles, it also has a range of challenges when it comes to embracing producers and enterprises.

Surmounting IIoT Integration Issues:

1.) Interoperability:

The processes included in the production in various industries differ. For the industrial industries, there are no standards or collections of industrial intelligent sensors. For instance, it can be a challenge to move data from different suppliers between machines within an ecosystem. Standards like Zigbee and Thread have allowed for improved interoperability between devices, but for Industry 4.0 similar standards have not been set. To ensure the interoperability of the business unit based on current systems, operators, and small businesses will have to change/digitalize their process.

2.) Security:

Securing smart technology is unnecessary if it does not have an interconnected system. The accessory of machines of industry class to a network, however, poses risks. It can lead to vulnerabilities and can cause the fault of the manufacturing process, potentially putting the safety of employees and machines at stake. It is a must for Industry 4.0 OEM to have the most robust and secure environment possible to protect from cyber threats.

3.) Deficient Expertise Amongst Manufacturing Makers:

Some marketing skills are still missing or difficult to find as IIoT is still in the early stages. Things such as hardware alignment, data integration from multiple sources, and the awareness of vendors can all prove difficult. Owing to a lack of expertise and large investment requirements, small-scale enterprises would find it hard to get started with Industry 4.0 technology.

4.) Reduction Of Proven Technology:

The industrial sector is significantly revolutionized by IoT. IoT helps to increase the productivity and effectiveness of different business processes and operations of manufacturing companies with the production of smart sensors, improved networking, and enhanced algorithms. IoT helps these businesses minimize manufacturing costs, helps to alleviate employee risk and also prevents machinery breakdowns. It strengthens logistics and streamlines them. It reduces the cost of distribution of goods and prevents wasting of money and time with better fleet management of company vehicles.

Use Of Smart Manufacturing Solution:

A smart manufacturing solution will help in phase-wise controlling manufacturing units and delivering asset failure reports. Industrial motor control and speed diagnostics will also support this approach. This approach would have a cloud interface to monitor and manage output remotely.

Conclusion:

IoT helps to increase the productivity and effectiveness of different business processes and operations of manufacturing companies with the production of smart sensors, improved networking, and enhanced algorithms. IoT helps these businesses reduce manufacturing costs, helps to alleviate employee risk, and also prevents machinery breakdowns. It strengthens logistics and streamlines them. It reduces the cost of distribution of goods and prevents wasting of money and time with better fleet management of company vehicles.

About the Author:

About the Author:

We are very thankful to you for this information and we hope that you keep giving us similar information.

Welcome here and thanks for reading our article and sharing your view. This will be very helpful to us to let us motivate to provide you more awesome and valuable content from a different mind. Thanks again.

I am very thankful.! useful information

Welcome here and thanks for reading our article and sharing your view. This will be very helpful to us to let us motivate to provide you more awesome and valuable content from a different mind. Thanks again.